Short Sleeve Hooded Sweatshirts: The Latest Craze in Little League Baseball

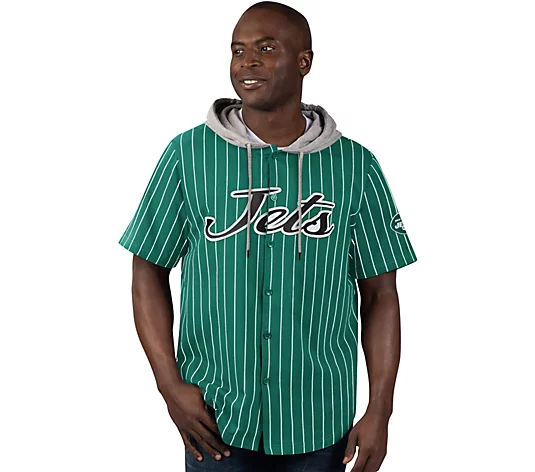

As the baseball season swings into full gear, Little League coaches are stepping up their game, not just on the field but in team fashion as well. In a trend inspired by the flair of minor league teams, short sleeve hooded sweatshirts are becoming the must-have item for coaches and players alike. This versatile piece, which straddles the line between casual and athletic wear, is seeing a surge in popularity but isn’t as readily available in retail as one might expect. That’s where the creativity of customization comes into play.

Customization has always been at the heart of team sports. It’s about more than just a logo or a team name; it’s about identity, unity, and spirit. And with short sleeve hooded sweatshirts being the newest trend, many coaches are choosing to purchase blank apparel to personalize. Blankstyle steps up to the plate offering a plethora of options for teams to customize and make their own.

Customization has always been at the heart of team sports. It’s about more than just a logo or a team name; it’s about identity, unity, and spirit. And with short sleeve hooded sweatshirts being the newest trend, many coaches are choosing to purchase blank apparel to personalize. Blankstyle steps up to the plate offering a plethora of options for teams to customize and make their own.

From the dugout to the batting cages, these short sleeve hooded sweatshirts offer a comfortable, stylish alternative to traditional baseball gear. They’re perfect for the unpredictable weather of spring and fall seasons, providing enough warmth without the full coverage of long sleeves that can restrict movement. So if you’re looking to recreate an aesthetic similar to this shirt by the Angels, then keep on reading!

Short Sleeve Sweatshirt Blanks

Sport Tek ST297 Sport-Tek PosiCharge Tri-Blend Wicking Fleece Short Sleeve Hooded Pullover in Dark Grey HTHR

Our selection includes favorites like the Sport Tek ST297 Sport-Tek PosiCharge Tri-Blend Wicking Fleece Short Sleeve Hooded Pullover. This particular model is a hit for its moisture-wicking fabric, keeping players cool and dry even as the game heats up. For those seeking a lighter option, the A4 N3408 – Cooling Performance Short Sleeve Hooded Tee is an excellent choice with its performance fabric. And let’s not forget the A4 N3410 – Cooling Performance Sleeveless Hooded T-Shirt for the ultimate combination of breathability and freedom of movement.

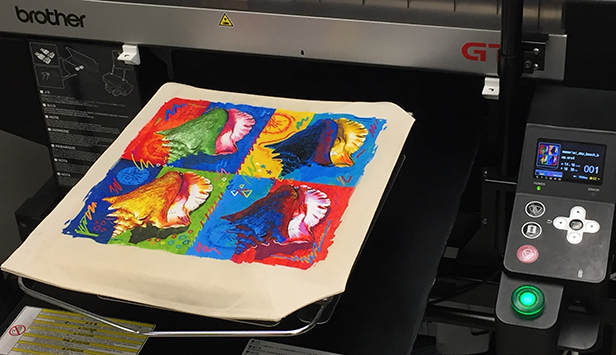

Whether you’re in search of a womens short sleeve hooded sweatshirt or men’s short sleeve hooded sweatshirts, Blankstyle has got your team covered. We understand the need for quality and affordability, which is why we offer these garments as short sleeve sweatshirt blanks, ready for your team’s unique customization. At Blankstyle, customization isn’t just an option; it’s an invitation to showcase your team’s personality and cohesion. Our in-house decoration team stands at the ready, equipped with an extensive array of options and methods to bring your vision to life. Screen printing offers a classic and bold statement for those eye-catching, full-front designs, ensuring your team’s logo stands out in the crowd and on the field.

For a touch of elegance and a smaller, more detailed aesthetic, embroidery remains a top choice. It’s perfect for those seeking a refined and durable embellishment, ideal for smaller logos that speak volumes through quality and design. Whichever path you choose, Blankstyle is committed to delivering a swift and satisfactory experience, ensuring your team steps out not just in style, but with confidence.

With Blankstyle, you’re not just buying a product; you’re creating a piece of your team’s story. We are dedicated to providing a seamless service that matches your team’s pace, ensuring you receive your decorated apparel swiftly and without hassle. So step up to the plate and let us hit a home run together with apparel that your team will wear with pride.

Custom team apparel has never been easier or more accessible. At Blankstyle, we provide the canvas, and you bring your team’s vision to life. Gear up for the season with the latest in baseball apparel trends and give your team the winning edge in both performance and style. Visit our website to explore our extensive range of short sleeve hooded sweatshirts and start designing your team’s next iconic look today.