World Design Day

With World Design Day igniting creativity across the globe, there’s no better time to craft the perfect shirt for your business. In a world where the first impression is often the last, a uniquely designed custom tee can set your brand apart, convey your company’s ethos, and establish a lasting connection with your audience.

Custom Tee

When embarking on creating a unique custom polo shirt design, it’s crucial to consider the message you want to relay. Your apparel is not just a piece of fabric; it’s a communication tool. Do you want to evoke professionalism? Perhaps a sense of approachability? Or maybe your brand is all about bold innovation? The design you choose will speak volumes before a word is even uttered.

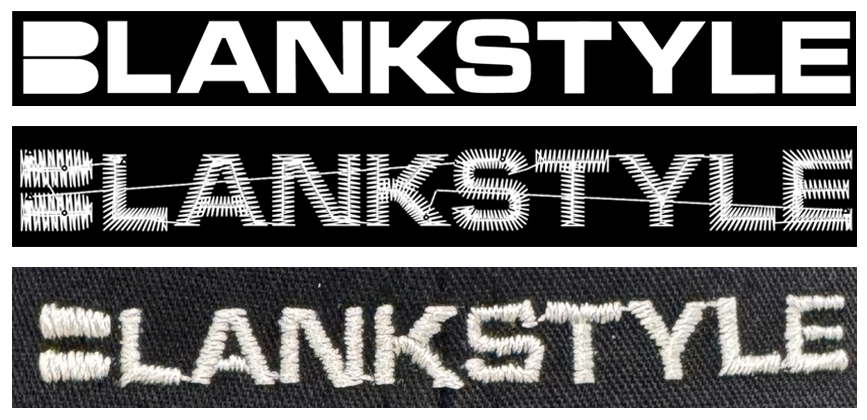

Embroidery Services Explained

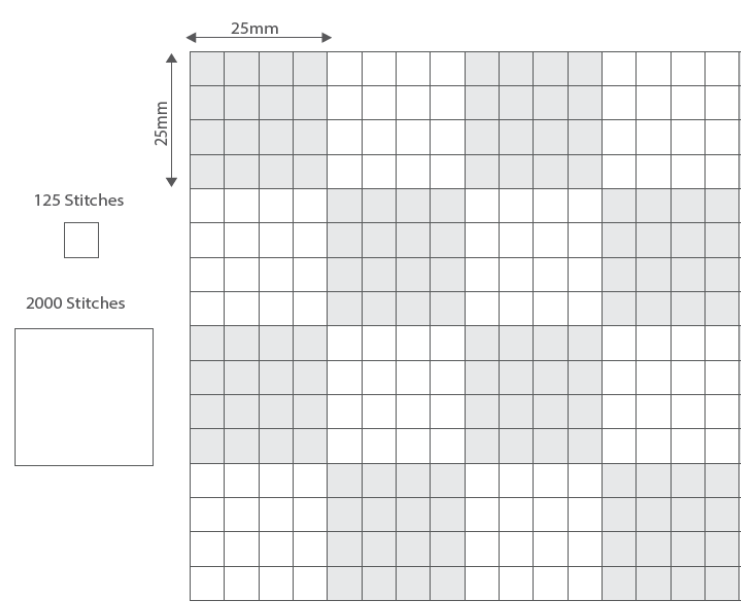

Embroidery offers a touch of elegance and professionalism to any garment. Digitizing your design is a crucial step, transforming it into a format that embroidery machines can read. At Blankstyle, we specialize in converting your designs with precision, ready to be embroidered onto hats, bags, or any heavy apparel. Embroidery pricing is based on the stitch count. Blankstyle offers an easy-to-use Stitch Count Estimator to help you calculate the stitches required for your design, allowing for precise budgeting and planning.

Embroidery begins with the art of digitization, where original artwork is meticulously transformed into a stitch pattern compatible with embroidery machines. If you want to understand the nature of your unique customized polo shirt design, you must first understand what it takes to make that design. The intricacies of this process, from the stitch count to the time and materials involved, are integral to determining the embroidery pricing. Unlike instant transformations, digitizing is an intricate art that demands time and expertise, forming an essential pre-embroidery cost. For practical cost estimation, the stitch count is projected through an educated estimation for your custom tee project, predicting the number of stitches that will ultimately define the digitized design’s complexity and price.

Custom t-shirt printing opens the door to unparalleled personalization, giving businesses the power to create a distinctive and unique customized polo shirt design that stands out. From selecting the ideal fabric to choosing the perfect ink for printing, each choice is a critical note in the symphony of design that will resonate with your brand’s identity. Embroidery, often the star of the show on polos and sturdier materials, adds a refined touch to your statement piece, ensuring every aspect of your custom design harmonizes with your branding strategy.

Unique Customized Polo Shirt Designs

In the world of custom apparel, the unique customized polo shirt design holds a prestigious spot. Polos have transcended time, maintaining a classic appeal while offering a modern canvas for personalization. When it comes to polo shirts, the embroidery method shines, elevating the garment with a touch of sophistication and durability suited for corporate wear or casual elegance compared to your average custom tee.

In the world of custom apparel, the unique customized polo shirt design holds a prestigious spot. Polos have transcended time, maintaining a classic appeal while offering a modern canvas for personalization. When it comes to polo shirts, the embroidery method shines, elevating the garment with a touch of sophistication and durability suited for corporate wear or casual elegance compared to your average custom tee.

By integrating a customized polo shirt design into your branding or personal style, you assert a level of professionalism and attention to detail that screen printing on other garments might not convey. Whether it’s for a company uniform, a golf event, or just a stylish twist to everyday wear, a uniquely embroidered polo can make a lasting impression. Blankstyle understands the significance of such tailored designs and offers a wide selection of polo shirts that can be customized to fit your specific aesthetic and branding needs.

As you dive into designing, consider the longevity of your design. Trends come and go, but a timeless design can transcend the fluctuating tides of fashion. Aim for a balance between contemporary appeal and enduring style. This ensures your custom tees remain relevant and treasured wardrobe staples for years. Smaller designs, text-based motifs, and illustrations are best suited for embroidery. These types of designs ensure clarity and aesthetic appeal on various garments. Blankstyle excels in bringing your creative ideas to life with high-quality embroidery.

Does Blankstyle have a contract embroidery shop near me?

At Blankstyle, we understand the importance of quality and efficiency in custom apparel branding. That’s why we offer professional contract embroidery services, tailored for businesses that aim to leave a lasting impression through exquisitely embroidered garments. With our competitive bulk pricing, it becomes a practical choice to entrust us with your embroidery needs, especially when working with exclusive retail brands like Gfore, Carhartt, and Nike that mandate reseller-completed embroidery services.

For those who possess their own embroidery setup and wish to cater to a local clientele, collaborating with Blankstyle could be your strategic move to expand. While you focus on cultivating local relationships and managing in-house production, we’ll take care of the intricate embroidery, ensuring it meets the high standards your customers expect. Plus, with our blind shipping service, your customers will receive their orders directly from our nearby facilities, as if they were shipped from your shop, allowing you to maximize the use of your machines and elevate the capacity of your business’s embroidery services.

Screen Printing vs. Embroidery

Screen printing is ideal for large volume orders with fewer colors, offering economic production and vibrant designs. Embroidery, on the other hand, adds a premium and detailed finish, perfect for logos and sophisticated patterns.

Moreover, it’s not just the visual elements that matter; functionality plays a significant role. A well-designed shirt is one that’s comfortable to wear and fits the intended purpose, whether it’s for casual Fridays at the office or as part of a uniform for staff at corporate events. The right material and fit are as important as the logo emblazoned on the chest.

Custom Design T Shirt Printing

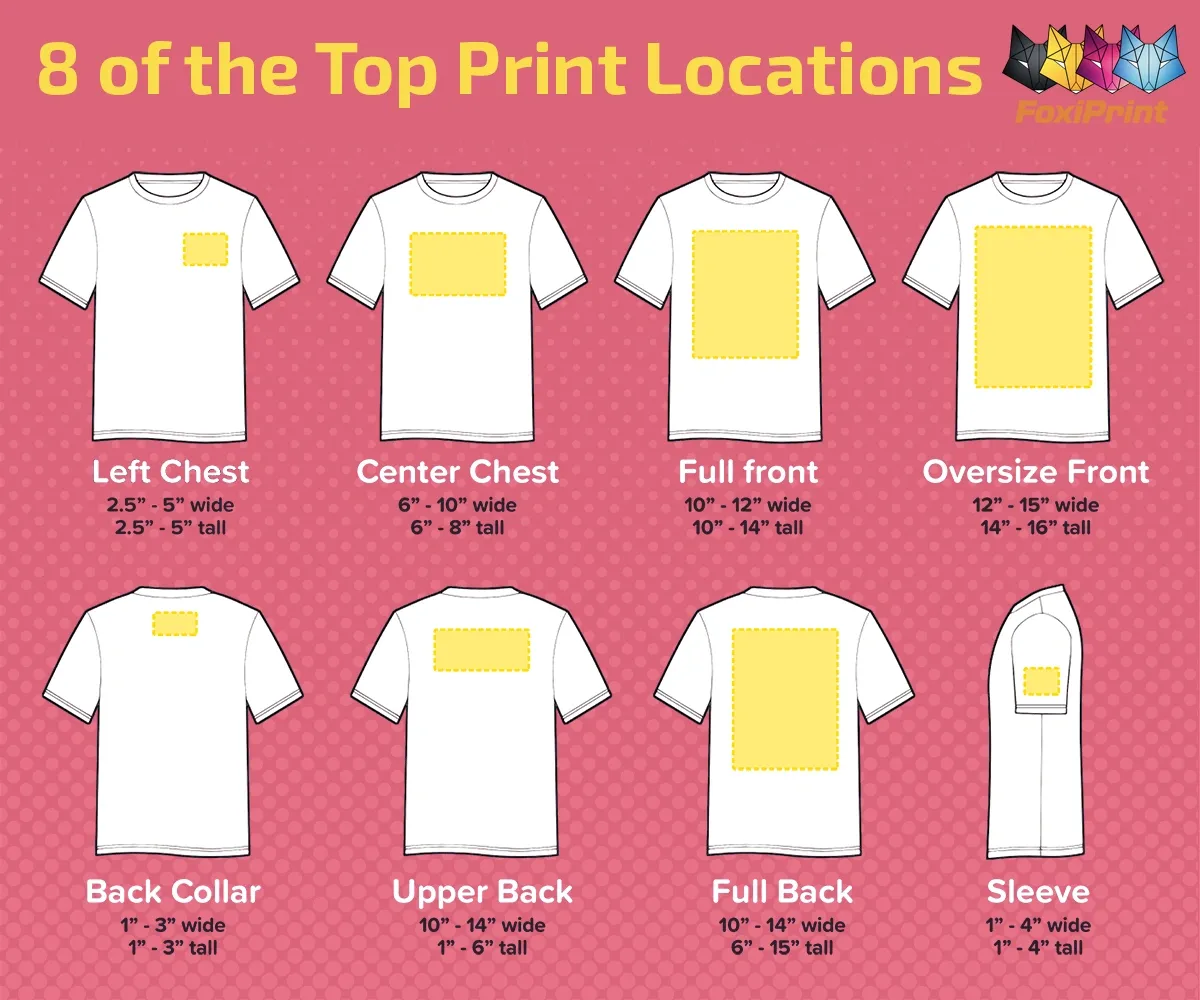

This image provides a detailed guide to the top eight print locations on a t-shirt for customization and branding. The “Left Chest” area, suitable for logos and emblems, spans approximately 2.5 to 5 inches in width and height. The “Center Chest” is slightly larger, offering a space of 6 to 10 inches wide and 6 to 8 inches tall for more prominent designs.

For maximum visibility, the “Full Front” section allows for designs that are 10 to 12 inches wide and 10 to 14 inches tall, while the “Oversize Front” goes even larger at 12 to 15 inches wide and 14 to 16 inches tall, making a bold statement. On the reverse side of the tee, the “Back Collar” offers a discreet branding opportunity with a 1 to 3-inch print area, and the “Upper Back” gives a generous canvas of 10 to 14 inches in width and 1 to 6 inches in height.

For full coverage, the “Full Back” can accommodate designs that are 10 to 14 inches wide and 6 to 15 inches tall. Lastly, the “Sleeve” print location is ideal for small badges or text, ranging from 1 to 4 inches both in width and height, providing a subtle yet stylish branding element. Each of these locations allows for creative expression for your custom tee and impactful brand placement on custom apparel.

Plastisol ink is renowned for its longevity and precise color-matching, perfect for an array of designs, including text-heavy graphics. It’s versatile enough for light and dark fabrics alike, with the thickness of the print depending on the number of colors in the design.

Plastisol ink is renowned for its longevity and precise color-matching, perfect for an array of designs, including text-heavy graphics. It’s versatile enough for light and dark fabrics alike, with the thickness of the print depending on the number of colors in the design.

For those desiring a softer print, Soft-Feel Plastisol is a variant that allows the fabric’s texture to peek through, offering a lighter touch to the print. This method thins the plastisol, making it semi-transparent, which is not ideal for dark garments due to its subtlety. While this approach may limit exact color matching, it’s perfect for lighter fabrics where a more subdued print is desired. Consultation with our expert customer service can guide you through this nuanced process.

Water-based Discharge printing is another alternative for those seeking the lightest touch in screen printing. This method bleaches the fabric color before applying ink, leaving behind a soft print that feels as if it’s part of the shirt. However, because it alters the fabric’s original color, the outcome might slightly differ from the intended design, especially if not printed on white. This technique is exclusive to 100% cotton garments to ensure the ink adheres properly and color matches are as accurate as possible.

Ink Effects

Additional screen print processes that we offer include metallic foils, Crystalina overlay, metallic inks, and puff ink! The foil method is great for anyone looking to make a statement to their custom tee or add some lightweight bling to their print! This is applied by first laying down a layer of glue to the desired areas on the garment, and then laying a chrome foil over the glue. Heat is applied to bond the two together, and the end result is a bright, flashy metallic finish.

Color options are limited to the foil colors that we offer. Crystalina overlay adds depth and sparkle to your design by laying a thick, translucent layer with colored shimmer over specified colors within your design for your custom tee. Crystalina adds just the right amount of sparkle, and is great for women’s and children’s designs. It can be applied to only one color layer, or your entire design.

World Design Day Should Inspire!

On World Design Day, we recognize the power of thoughtful design in shaping perceptions and creating memorable brands. Your custom tees are not just attire; they’re walking billboards that can amplify your brand’s presence in the world. So take this opportunity to unleash your creativity, collaborate with seasoned designers, and craft that perfect piece of apparel that embodies the essence of your business.

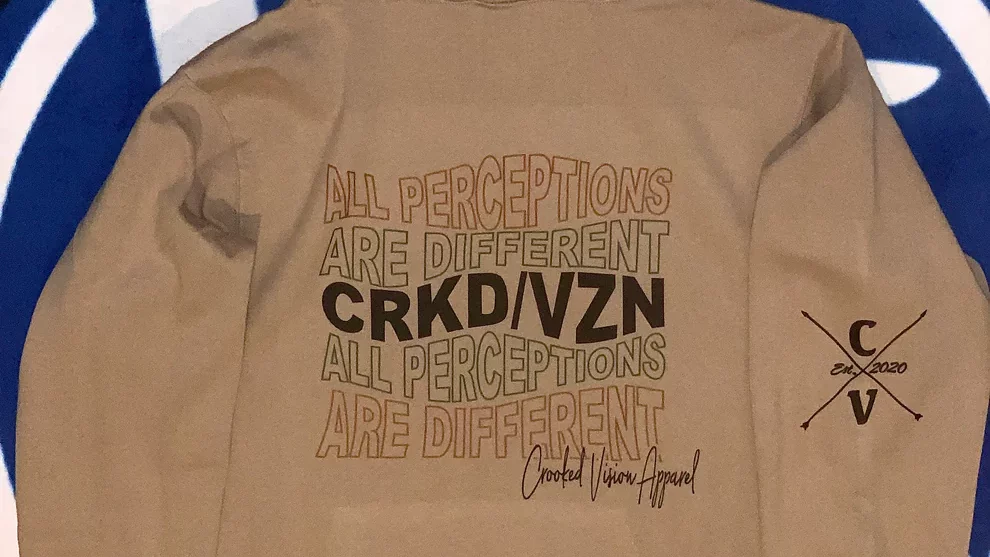

Brands That Have Been Inspired by us

Blankstyle has had the privilege of collaborating with a diverse range of businesses and brands, each with their own unique story and mission. Our experience with these partnerships has not only enriched our portfolio but also allowed us to play a role in their success.

One such brand is Training Day Media, whose dedication to positive reinforcement and motivational content truly sets them apart. With a focus on themes of strength and personal achievement, their content serves as a daily dose of inspiration to their audience. Their goal to ignite creativity and encourage others to pursue their passions aligns perfectly with our mission at Blankstyle. We provided the perfect apparel that resonated with their brand voice, helping them to weave their empowering messages into wearable art. Their vision is a testament to the power of positive messaging and the impact it can have on a community.

Another brand that stands out in our collaborative history is Synister Clothing, a brand that champions the ethos of non-conformity. Synister Clothing has built a sanctuary for the individuals who find solace in the goth and emo subcultures of the early 2000s. They’ve managed to tap into a niche market with precision and authenticity, capturing the attention of over 24,000 followers across social media platforms. This impressive reach is a clear indicator of their resonating appeal and their ability to grow a dedicated fan base. Blankstyle has proudly supplied them with high-quality apparel that serves as the foundation for their unique designs, playing a part in the expression of individuality that their brand encourages.

Our collaboration with CHOMP by Joshua Ariza epitomizes the fusion of fashion and art. Joshua’s 15-year tenure in design for prominent lifestyle brands brings a wealth of experience to his personal project. His custom tee’s at CHOMP stands out for its compelling artwork, which transforms ordinary apparel into extraordinary statements. By selecting Blankstyle for their apparel needs, CHOMP ensures each piece reflects the high standards of quality and creativity they’re known for. It’s a partnership that exemplifies the power of wearable art to express identity and innovation.

These collaborations have not only enriched the brands we’ve worked with but have also allowed Blankstyle to refine our understanding of the diverse needs of our customers. We look forward to fostering more partnerships with businesses and brands that seek to make a difference through their products and messages. Whether it’s a startup or an established company, Blankstyle is dedicated to providing top-notch services that complement and elevate the vision of our clients.

Top T-Shirts Used for Custom Tee’s

In their recent creative endeavor, CHOMP clothing turned to Blankstyle for high-quality apparel, handpicking the Cotton Heritage MC1082 for its superior comfort and construction. Joshua Ariza’s vision comes to life on this ideal blank, particularly with their Florida Flamingo shirt, a piece that perfectly encapsulates CHOMP’s aesthetic. The shirt features a captivating and playful homage to Florida, illustrated with a fresh palette of teal and coral that captures the state’s tropical charm, all set upon a subtle, sandy-colored base. The brand has also experimented with other quality garments like the M&O Knits 6500M, finding a complementary backdrop in the Cotton Heritage MC1082’s versatile sand shade.

In their recent creative endeavor, CHOMP clothing turned to Blankstyle for high-quality apparel, handpicking the Cotton Heritage MC1082 for its superior comfort and construction. Joshua Ariza’s vision comes to life on this ideal blank, particularly with their Florida Flamingo shirt, a piece that perfectly encapsulates CHOMP’s aesthetic. The shirt features a captivating and playful homage to Florida, illustrated with a fresh palette of teal and coral that captures the state’s tropical charm, all set upon a subtle, sandy-colored base. The brand has also experimented with other quality garments like the M&O Knits 6500M, finding a complementary backdrop in the Cotton Heritage MC1082’s versatile sand shade.

For their bespoke creations, Synister Clothing selected the robust and comfortable Alstyle 1301 Heavyweight T-Shirt by American Apparel in a sleek black, seeing it as the quintessential foundation for their unique custom tee’s designs. Synister Clothing’s offerings are meticulously crafted upon order, underscoring the brand’s dedication to exclusivity and individual expression. Their preference for the Alstyle 1301 is a testament to their pursuit of excellence, signaling that they value high-quality materials as the cornerstone of exceptional apparel.

For their bespoke creations, Synister Clothing selected the robust and comfortable Alstyle 1301 Heavyweight T-Shirt by American Apparel in a sleek black, seeing it as the quintessential foundation for their unique custom tee’s designs. Synister Clothing’s offerings are meticulously crafted upon order, underscoring the brand’s dedication to exclusivity and individual expression. Their preference for the Alstyle 1301 is a testament to their pursuit of excellence, signaling that they value high-quality materials as the cornerstone of exceptional apparel.

Over the last three years, Blankstyle has proudly served as the go-to resource for Training Day Media, furnishing the ideal backdrop for their signature creations. Favorites such as the Bella Canvas Soft Cotton T-Shirt and the Bella + Canvas Fast Fashion Heavyweight Street Tee have been staples in showcasing their brand’s unique message, amplifying their reach to a broader audience.

Over the last three years, Blankstyle has proudly served as the go-to resource for Training Day Media, furnishing the ideal backdrop for their signature creations. Favorites such as the Bella Canvas Soft Cotton T-Shirt and the Bella + Canvas Fast Fashion Heavyweight Street Tee have been staples in showcasing their brand’s unique message, amplifying their reach to a broader audience.

Custom design t shirt printing opens the door to unparalleled personalization, giving businesses the power to create a distinctive and unique custom polo shirt design that stands out. From selecting the ideal fabric to choosing the perfect ink for printing, each choice is a critical note in the symphony of design that will resonate with your brand’s identity. Embroidery, often the star of the show on polos and sturdier materials, adds a refined touch to your statement piece, ensuring every aspect of your custom design harmonizes with your branding strategy.

Let World Design Day be the spark that ignites your creative spirit and propels your brand into uncharted territories of innovation. At Blankstyle, we’re not just a service; we’re a conduit for your imagination. We invite you to dive into the rich educational resources we’ve curated, guiding you to uncover the potential of your next big project. Whether it’s exploring the vibrant world of screen printing, delving into the intricate art of embroidery, or venturing into the realm of Direct to Garment (DTG) printing, our platforms are designed to enlighten and inspire. With us at your side, the journey from concept to creation is boundless.

Unlock the door to a universe where your vision is translated into a tangible custom tee with memorable designs that echo the essence of your brand. If you’d like a tutorial on how to use our services, check out this video here.

never the impression you want to make. With a printed label, your customers won’t ever have to fuss and fight. And with a bigger surface area than standard woven tags, you’ll have more freedom to really use the label as branding opportunity. Screen-printed custom shirt tags offer more room for artistic design that will have a presence on the garment—catching the eye of shoppers and leaving an impression about the identity of your brand. Custom garment labels also help to keep your t shirt line cohesive across different items, styles and colors. There’s no better way to legitimize your line and keep up with big brand names than to order your own custom screen printed labels!

never the impression you want to make. With a printed label, your customers won’t ever have to fuss and fight. And with a bigger surface area than standard woven tags, you’ll have more freedom to really use the label as branding opportunity. Screen-printed custom shirt tags offer more room for artistic design that will have a presence on the garment—catching the eye of shoppers and leaving an impression about the identity of your brand. Custom garment labels also help to keep your t shirt line cohesive across different items, styles and colors. There’s no better way to legitimize your line and keep up with big brand names than to order your own custom screen printed labels! How do you remove the existing garment tags?

How do you remove the existing garment tags? more ink there is in your print, the more you will feel it! Besides, you don’t want your label to distract from the rest of your shirt!

more ink there is in your print, the more you will feel it! Besides, you don’t want your label to distract from the rest of your shirt!