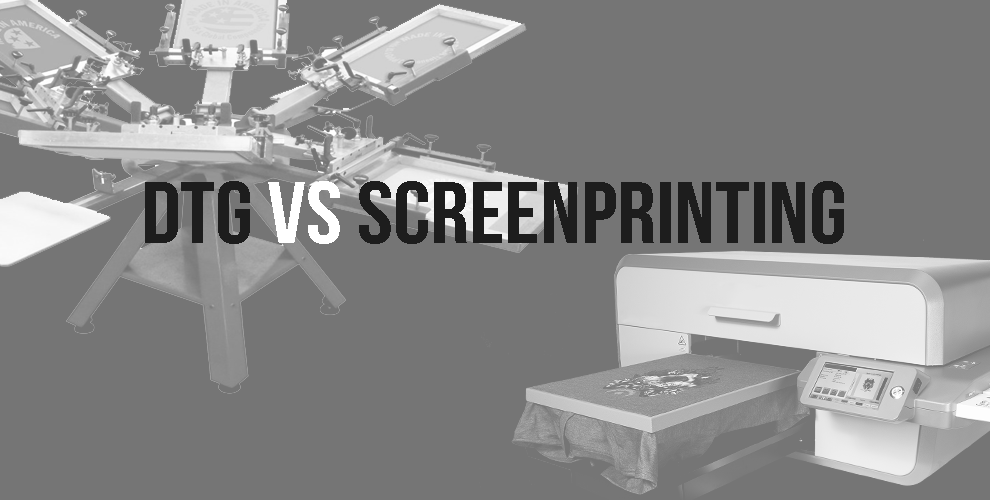

What is screen printing? As you might guess, given the obvious hint built into the name, screen printing is a printmaking technique where stencils are laid over a screen. That screen is usually made of cotton, nylon, or metal. The printing ink is then pushed through the screen using a rubber squeegee. That’s the simplified version, but every little step can involve lots of decisions from what ink to use to the best squeegee.

Image above: a screen printing class at the Alexandria Museum of Art

Just a little history

The basic process is thought to have been invented in China and then refined in Japan (makers of good things like karaoke, the novel, and instant ramen). After 1915, when it became possible to photo-screen print (introducing photo stencils), the technique took off in the commercial sector in the United States. Grocery stores and other shops needed quickly produced locally made signs to advertise sales, and screen printers were able to underbid sign painters and win jobs. For years, those screen printing techniques were closely guarded trade secrets. Then in the 1960s, the technique took off in the art world amongst pop artists like Andy Warhol, Roy Lichtenstein, and Richard Hamilton. From there, screen printing entered the mainstream. These days, screen printing has been enthusiastically adopted by the DIY community. And now that the information for how to set up a screen printing studio is so readily available online – anyone, with an idea, can screen print.

Image above: DIY Print Shop

Screen printing Setups

One of the reasons that screen printing is so popular is that it is infinitely scalable. You can create a setup for under $40 or spend $40,000. Every setup might be a little different, but the basic elements are a screen, emulsion, artwork, a squeegee, ink, a light source, and a water source. If you’re eager to get your hands dirty, this is a great screen printing guide from one of our favorite reads, LifeHacker. (But if you’d rather us do the dirty work, we’re happy to mess around with the ink for you.)

Image above: jacquard screen printing inks

Decision, Decisions, Decisions aka Screen Printing Ink

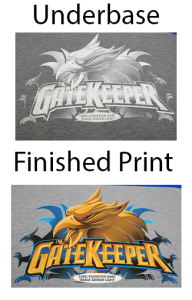

Underbase

The first consideration in design is often the underbase. One of the most important choices in determining how your design turns out, regardless of the ink type is whether or not an underbase is used. Think of an underbase like a primer coat. if you wanted to paint a red wall blue you would first prime the wall with a neutral color like gray or white, You would then paint blue over the primer. If you were to paint blue over the red wall without priming you would end up with a purple not a blue.

Underbasing in t-shirt printing, much like priming in painting is a great way to ensure your design ends up being the color you intended it to be. An underbase is essentially the entirety of your design printed in neutral ink. In this way regardless of the garment color or makeup the colors in your finished design should remain consistent. This is especially true when printing bright colors over darker colors. This is also true when your intention is to have a consistent-looking design printed on different material makeups and colors. There are a few negatives to consider when choosing to underbase. Because there is an additional underlay or undercoat of ink, the design will feel thicker to the touch. In addition, underbasing requires additional screens adding cost. Printers typically charge around $30 to $40 dollars per screen.

In a nutshell, if you are printing on lighter uniformly colored garments and the most important component of your finished design is its soft feel where color consistency takes a back seat, you should not be underbasing however if you are printing on dark or various colored garments and need a consistent design color where soft feel is the less important of the two, you should be underbasing. Often times printers will help you make this decision based on the garments you’ve chosen and the colors in your design.

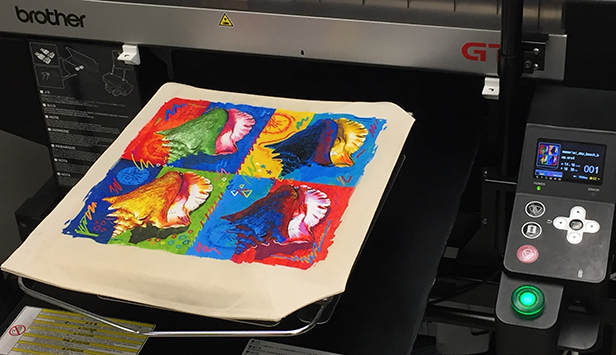

Ink types

Once you’ve decided on your shirt (and that’s a whole other conversation), the most important consideration is going to be your ink.

The traditional ink is plastisol ink. This creates a thick print that rests on top of the shirt. Plastisol inks can provide a higher contrast than water-based ink, and if you’d like your  printed design to appear bright and color accurate, then a plastisol ink can give you that effect. Plastisol ink is a good choice if you’re printing sporting goods, nylon, or dark-colored clothing. Plastisol ink is also the most consist

printed design to appear bright and color accurate, then a plastisol ink can give you that effect. Plastisol ink is a good choice if you’re printing sporting goods, nylon, or dark-colored clothing. Plastisol ink is also the most consist ent choice when printing the same design on different garment styles and or colors.

ent choice when printing the same design on different garment styles and or colors.

If you’re looking to make a super soft shirt then water-based ink is where it’s at. Whereas the plastisol ink rests on top of the shirt, water-based ink is actually directly dying, or in the case of discharge, bleaching the fabric’s fibers, which means that the printed portion of the shirt will remain softer than plastisol the print further softens to almost a no feel with one washing. An added plus is that water-based ink is eco-friendly. Water-based inks don’t have that same high contrast that plastisol inks have so the effect often feels vintage. Waterbase ink typically work out best when the design has a limited color spectrum as water base inks are not vibrant like plastisol inks. Creative designers typically use the garment color to bring out accents in the design.

But there is a middle ground between plastisol and water-based – soft plastisol or soft-hand plastisol gives you the contrast of a plastisol ink but is much softer than the straight-up plastisol ink. Soft hand plastisol is accomplished by using thinning agents and high mesh count screens minimizing and thinning the amount of ink allowed to pass through the screen to the garment.

But what if you want a more custom look? There are an infinite number of special effects inks. Here are a few of our favorites and the ones that we print with here at Blankstyle.com.

Puff ink is the screen printer’s version of that ‘80s craft favorite – puff paint. Puff ink is created by mixing an additive with the plastisol inks so that your ink will puff up after it dries giving your design a textured effect. (We like to use it to give your designs a faux stitching effect.)

So that’s the quick run-down on what screen printing is and how it’s done. Of course, the more you dig around, the more questions you might have. We’re here to help with any of those.

And if you prefer to get your information the old-fashioned way, here are some great resources:

Print Liberation: The Screen Printing Primer

Simple Screenprinting: Basic Techniques & Creative Projects

ulled: A Catalog of Screen Printing (great for inspiration)